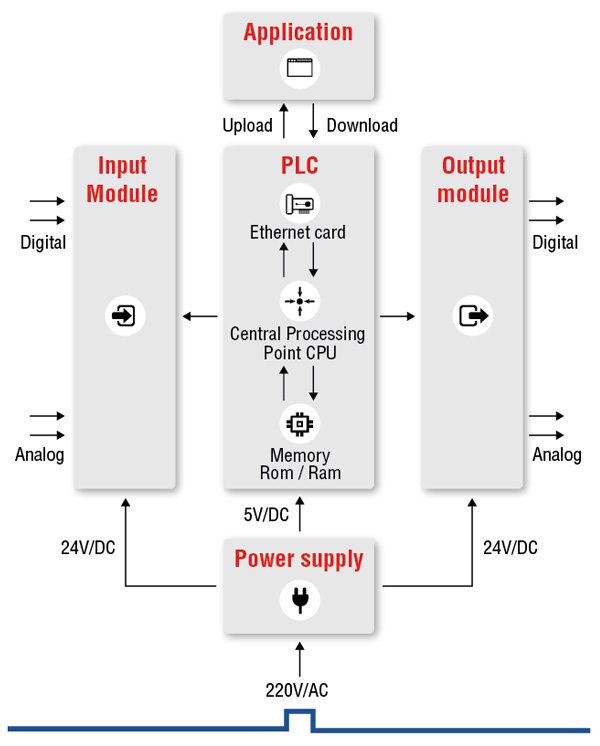

A Programmable Logic Controller, or PLC, is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.The PLC receives information from connected sensors or input devices, processes the data, and triggers outputs based on pre-programmed parameters. Depending on the inputs and outputs, a PLC can monitor and record run-time data such as machine productivity or operating temperature, automatically start and stop processes, generate alarms if a machine malfunctions, and more. Programmable Logic Controllers are a flexible and robust control solution, adaptable to almost any application • I/O – The PLC’s CPU stores and processes program data, but input and output modules connect the PLC to the rest of the machine; these I/O modules are what provide information to the CPU and trigger specific results. I/O can be either analog or digital; input devices might include sensors, switches, and meters, while outputs might include relays, lights, valves, and drives. Users can mix and match a PLC’s I/O in order to get the right configuration for their application. • Communications – In addition to input and output devices, a PLC might also need to connect with other kinds of systems; for example, users might want to export application data recorded by the PLC to a supervisory control and data acquisition (SCADA) system, which monitors multiple connected devices. PLCs offer a range of ports and communication protocols to ensure that the PLC can communicate with these other systems. • HMI – In order to interact with the PLC in real time, users need an HMI, or Human Machine Interface. These operator interfaces can be simple displays, with a text-readout and keypad, or large touchscreen panels more similar to consumer electronics, but either way, they enable users to review and input information to the PLC in real time